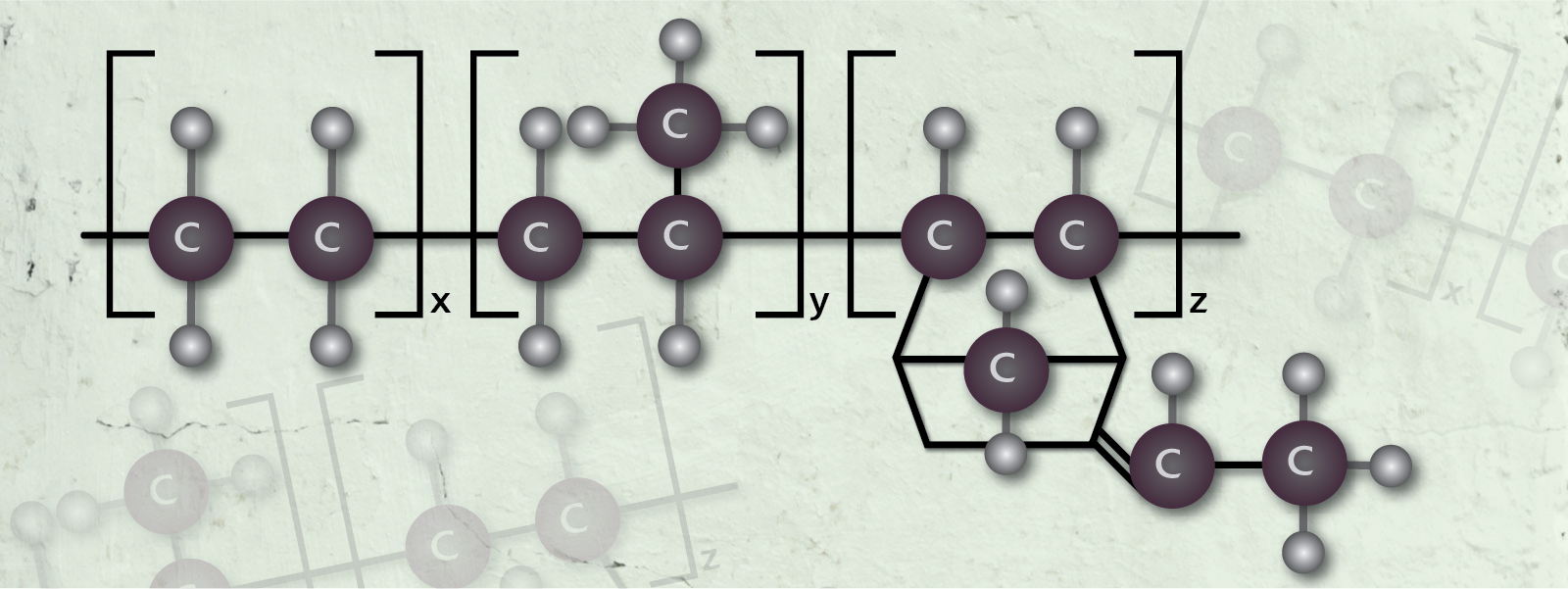

Ethylene-Propylene Diene (EPDM Rubber)

EPDM Rubber is a synthetic rubber with very good performance utilized in a wide range of applications.

Ethylene-Propylene Diene (EPDM Rubber)

EPDM Rubber is mainly used in seals for plumbing, potable water systems (certifiable to NSF std. 61), roofing membranes, wide-ranging automobile applications (door, trunk and window seals), heating systems, hoses and various industrial products. Capable of being compounded with high filler loads.

Because of a stable saturated polymer backbone construction it is resistant to heat, oxidation, ozone and UV weather aging. It is a non-polar elastomer with decent electrical resistivity and resistance to polar solvents like water, acids, alkalies, phosphate esters, and many ketones and alcohols. Able to achieve a wide temperature range from -58° to 320°F.

EPDM’s are compounded with sulfur or peroxide cure systems. Peroxide cure compounds are suitable for high temperature and typically have better compression set performance.

EPDM compounds are not recommended for exposure to petroleum oils, fuel, mineral oil and aromatic hydrocarbons.

Material Specifications

- Hardness: 30 to 95 – Shore A

- Tensile Strength: > 2,000 PSI

- Elongation: 100% to 600%

Contact Lavelle Today

Tell us a bit more about yourself and your project needs and our sales team will contact you to formalize an estimate.

Get Started